Sourcing the right fabric is the cornerstone of success in apparel manufacturing, home décor, and the broader textile industry. As one of the world’s leading textile producers and exporters, India offers an incredibly diverse range of fabrics – from luxurious handwoven silks and organic cottons to budget-friendly synthetics and innovative technical textiles. Whether you are a fashion designer, textile entrepreneur, or a home décor brand, knowing how to source quality fabric effectively can make all the difference in your product’s quality, cost, and sustainability.

What Is Fabric Sourcing and Why Does It Matter?

Fabric sourcing is the process of identifying, evaluating, and purchasing textiles that align with your product’s design requirements, budget constraints, and sustainability goals. The fabric you choose plays a critical role in the final product’s aesthetic, performance, and lifecycle. It affects everything from the garment’s drape and texture to how well it withstands washing and wear.

Moreover, fabric sourcing directly impacts your production costs, compliance, and timelines. Choosing the wrong fabric or an unreliable supplier can lead to quality issues, delivery delays, and increased costs. In today’s market, where transparency and eco-consciousness are paramount, fabric sourcing is no longer just a supply chain activity but a strategic brand decision.

What are the categories of Fabric?

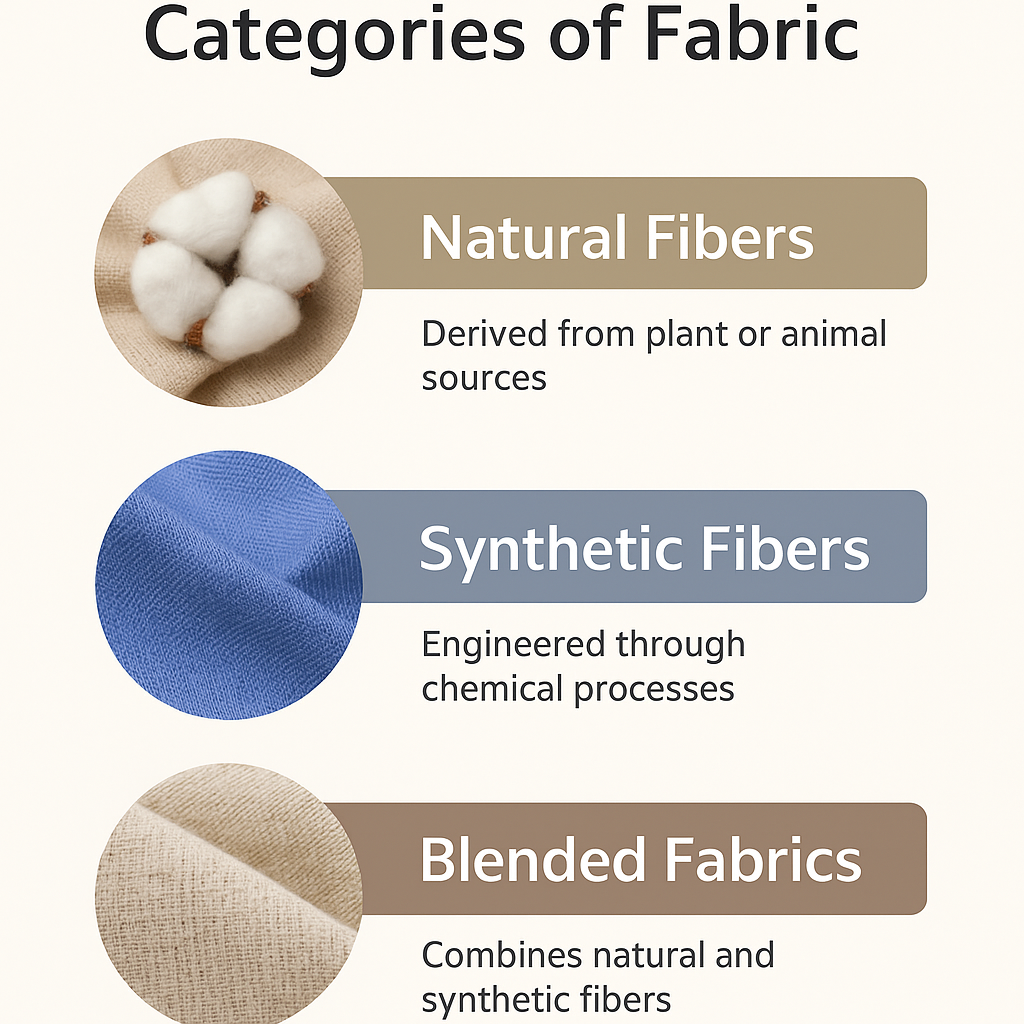

When sourcing fabric, it is essential to understand the main types of textiles available in the market:

- Natural Fibers: Derived from plant or animal sources such as cotton, silk, wool, and linen. These fabrics are breathable, biodegradable, and hypoallergenic. India is one of the largest producers of organic cotton globally and home to rich silk-producing regions like Assam and Karnataka.

- Synthetic Fibers: Engineered through chemical processes, synthetic textiles like polyester, nylon, and acrylic are known for their durability, wrinkle-resistance, and affordability. Surat is a major hub for synthetic fabric manufacturing.

- Blended Fabrics: These combine natural and synthetic fibers to balance aesthetics, performance, and cost. Examples include cotton-polyester, silk-cotton, and viscose blends which offer enhanced comfort, durability, and processing ease.

Understanding fiber properties helps you select the right fabric for specific applications such as activewear, evening gowns, uniforms, or home textiles.

Why Choose India for Fabric Sourcing in 2025?

India is a global textile powerhouse, with FY 2023–24 textile and apparel exports (including handicrafts) valued at approximately $34–35.9 billion, according to multiple official sources including the Ministry of Textiles. The country ranks as the 6th largest exporter of textiles and apparel globally, holding about a 4% share in global trade. India’s textile legacy is enriched by centuries of weaving traditions, yet it is also advancing through modern innovations in technical and recycled fabrics.

India’s Competitive Advantages:

- Diversity: Offers traditional handlooms like Banarasi, Chikankari, and Kalamkari alongside industrial synthetics and performance fabrics.

- Affordability: Low labor costs and abundant raw materials make Indian textiles competitively priced.

- Skilled Workforce: Home to millions of skilled weavers, dyers, and tailors across organized and unorganized sectors.

- Eco-Initiatives: Increasing adoption of GOTS-certified organic cotton, solar-powered mills, and zero-liquid discharge dyeing units.

Key Considerations Before Sourcing Fabric

Before you initiate contact with any fabric supplier or manufacturer, take the following aspects into account:

- Quality Checks: Examine texture, GSM (grams per square meter), weave tightness, dye quality, and finish. Testing for pilling, shrinkage, and tensile strength is vital.

- Pricing Structure: Analyze costs considering bulk rates, domestic vs. import pricing, and applicable taxes like GST (currently 5–18% based on fabric type).

- Sustainability and Certifications: Look for GOTS, OEKO-TEX, ISO 14001, and Fair Trade. Ask about chemical usage in dyeing and environmental practices.

- Lead Time: Ensure that fabric availability and shipment dates match your production cycles. Confirm if stock is ready-to-dispatch or made-to-order.

- Supplier Verification: Cross-check business registration (Udyam, GSTIN), online reviews, and sample quality. A reputable supplier communicates proactively and transparently.

Step-by-Step Process to Source Fabric in India

1. Define Your Requirements

Begin by outlining:

- Fabric type: e.g., 100% organic cotton, bamboo viscose, recycled polyester

- Quantity: Define in meters/yards with buffer for sampling and QC

- Usage: Apparel (menswear, womenswear), furnishings, accessories

- Performance needs: e.g., moisture-wicking, wrinkle resistance

- Required certifications

2. Research Suppliers

Search both online and offline:

- Markets: Surat Textile Market, Chandni Chowk, Erode Powerloom Market

- Trade Shows: Gartex, IndiaTex, Bharat Tex, Heimtextil India

- Online Platforms: IndiaMART, TradeIndia, Textile Infomedia, Alibaba India

3. Connect with Manufacturers

- For large orders, collaborate with mills like Arvind Ltd, Raymond, Vardhman, Welspun

- For niche fabrics, approach co-operatives like Khadi India or artisan groups in Andhra Pradesh, West Bengal, and Rajasthan

4. Request and Test Samples

- Perform lab tests for dimensional stability, colorfastness (to light, wash, rub), tensile strength, and eco-standards

- Use physical samples to assess drape, stretch, opacity, and print clarity

5. Negotiate Terms

- Discuss MOQs (often 100–500 meters for prints), per-meter pricing, payment conditions (advance, L/C, credit), and delivery dates

- Clarify incoterms (FOB, CIF) and include GST/tax details in contracts

6. Ensure Compliance

- Request documentation for GOTS, Fair Trade, OEKO-TEX, ISO, etc.

- Confirm child labor policies, dyeing and finishing compliance, and social audits for export orders

7. Build Supplier Relationships

- Schedule regular follow-ups and progress checks

- Visit manufacturing units or use third-party agents for inspections

- Maintain ongoing collaboration to streamline repeat orders and reduce lead time

Top Fabric Markets Across India

| Market | Location | Speciality | Price Range |

| Surat Textile Market | Gujarat | Synthetics, sarees, printed dress fabric | Low to Medium |

| Gandhinagar Market | Ahmedabad, Gujarat | Cotton, denim, hand-block prints | Medium |

| Chandni Chowk | Delhi | All varieties including bridal fabrics | Low to High |

| Mangaldas Market | Mumbai | Premium, export-quality fabrics | Medium to High |

| Erode Market | Tamil Nadu | Power loom, cotton knits | Low to Medium |

| Sanganer | Jaipur, Rajasthan | Block prints, tie-dye, cotton | Medium |

| Varanasi | Uttar Pradesh | Banarasi silk, zari brocades | High |

Sourcing Sustainable Fabrics in India

India is gaining recognition for its commitment to eco-friendly textile production:

Key Sustainable Options:

- Organic Cotton: Certified by GOTS, major production in Gujarat and Madhya Pradesh.

- Khadi & Handloom Textiles: Includes Chanderi, Bhagalpuri silk, Pochampally ikat.

- Recycled Polyester: Upcycled PET fabrics manufactured in Surat and Ludhiana.

- Hemp & Bamboo Blends: Emerging sustainable options produced in limited clusters.

Policy Updates Affecting Fabric Sourcing in 2025

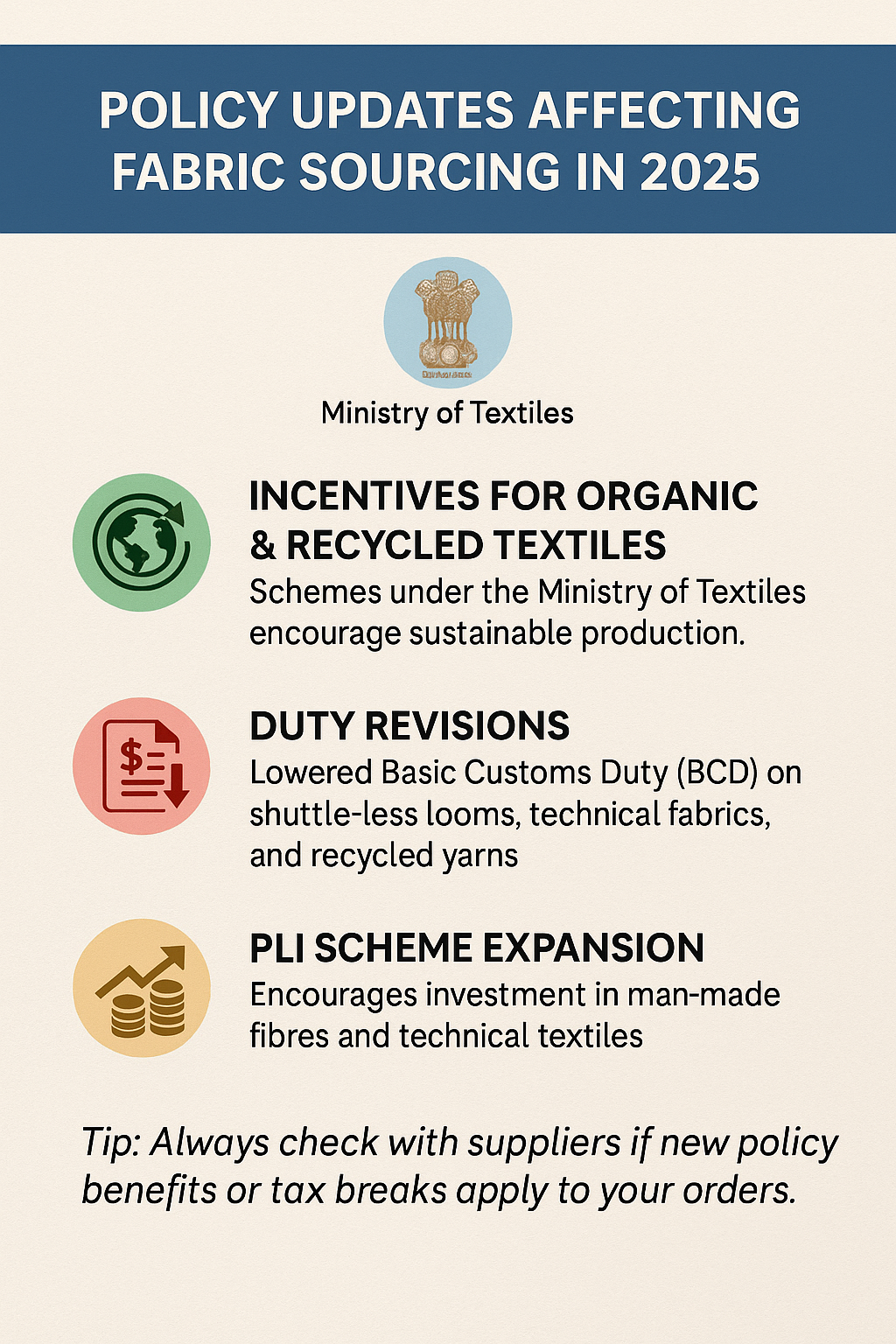

India’s textile policy landscape in 2025 supports manufacturing and sustainability:

- Incentives for Organic & Recycled Textiles: Schemes under the Ministry of Textiles encourage sustainable production.

- Duty Revisions: Lowered Basic Customs Duty (BCD) on shuttle-less looms, technical fabrics, and recycled yarns.

- PLI Scheme Expansion: Encourages investment in man-made fibers and technical textiles.

Tip: Always check with suppliers if new policy benefits or tax breaks apply to your orders.

Challenges and Pro Tips

Common Challenges:

- Fragmented supplier network with inconsistent quality

- Delayed deliveries due to transport and seasonal constraints

- Difficulty verifying sustainability claims

Expert Tips:

- Use IndiaMART, TradeIndia, and DGFT for registered supplier details

- Hire local sourcing agents or third-party QC companies (e.g., SGS, Intertek)

- Always place a small batch trial order before committing to bulk

- Insist on factory visits or live video walkthroughs for first-time orders

m8ty04

k35kfn

9e15ju

75lk5x

c24tiu

Can I just say what a relief to find someone who actually knows what theyre talking about on the internet. You definitely know how to bring an issue to light and make it important. More people need to read this and understand this side of the story. I cant believe youre not more popular because you definitely have the gift.

bxabei

h72rxh

0s0uks

bgqsqc

uzqrgk

vyc282

4hga18

v4b0rg

2tw8np

Hi there would you mind stating which blog platform you’re using? I’m looking to start my own blog soon but I’m having a hard time deciding between BlogEngine/Wordpress/B2evolution and Drupal. The reason I ask is because your layout seems different then most blogs and I’m looking for something completely unique. P.S Apologies for being off-topic but I had to ask!

wx0fpm

thv10e

1972y9

mi831e

t0a1xq

vtwll8

noy1jm

bq3580

v89aej

c2nmhp

i6r4dx

**mindvault**

mindvault is a premium cognitive support formula created for adults 45+. It’s thoughtfully designed to help maintain clear thinking

bmc1k8

**prostadine**

prostadine is a next-generation prostate support formula designed to help maintain, restore, and enhance optimal male prostate performance.

jvcn47

**sugarmute**

sugarmute is a science-guided nutritional supplement created to help maintain balanced blood sugar while supporting steady energy and mental clarity.

**glpro**

glpro is a natural dietary supplement designed to promote balanced blood sugar levels and curb sugar cravings.

06nsb8

l94yt6

**mitolyn**

mitolyn a nature-inspired supplement crafted to elevate metabolic activity and support sustainable weight management.

**zencortex**

zencortex contains only the natural ingredients that are effective in supporting incredible hearing naturally.

**prodentim**

prodentim an advanced probiotic formulation designed to support exceptional oral hygiene while fortifying teeth and gums.

**vitta burn**

vitta burn is a liquid dietary supplement formulated to support healthy weight reduction by increasing metabolic rate, reducing hunger, and promoting fat loss.

**yu sleep**

yusleep is a gentle, nano-enhanced nightly blend designed to help you drift off quickly, stay asleep longer, and wake feeling clear.

**synaptigen**

synaptigen is a next-generation brain support supplement that blends natural nootropics, adaptogens

**nitric boost**

nitric boost is a dietary formula crafted to enhance vitality and promote overall well-being.

**glucore**

glucore is a nutritional supplement that is given to patients daily to assist in maintaining healthy blood sugar and metabolic rates.

**wildgut**

wildgutis a precision-crafted nutritional blend designed to nurture your dog’s digestive tract.

As A End Result Of the “come down” on Anadrol is severe, we

sometimes see steroid customers opt for a milder steroid similar to Deca

Durabolin after coming off to assist this transition. Such a protocol may also assist users retain extra power and muscle features experienced from an Anadrol cycle.

We have found Anadrol to be one of the most deleterious anabolic steroids for blood strain.

All AAS will elevate a person’s blood stress as a result

of exogenous testosterone, causing a unfavorable

shift in cholesterol levels. This ends in a rise in LDL (bad) levels of

cholesterol and a lower in HDL (good) ranges. Some people consider Anadrol causes

fats gain; nonetheless, this isn’t accurate.

We have seen this stack add 30–40 pounds of weight acquire to customers, accompanied by 50–70 kilos of elevated strength on compound lifts.

Some of the burden gained might be within the form of

water; thus, bloating and water retention are probably, with

Dianabol having the aromatase enzyme energetic. All of this is essential as a outcome of

nitrogen retention and protein synthesis will velocity up muscle development

and restoration. In addition to that, higher glycogenolysis will

increase the pace of turning carbs into energy.

In a nutshell, Post Cycle Remedy is a recovery period

supposed to rehabilitate your body after a steroid cycle.

It’s an important step in the path of safeguarding your total health, maintaining the features made during the cycle, and making certain you’re reset

and prepared for any future bodybuilding ventures.

Taking Dianabol alone could provide some outcomes, however it’s

best time to take dianabol before or after workout

to stack it with other compounds for optimum advantages.

This is because Dianabol can have some negative side effects if it’s taken for too long.

This will assist maintain your blood ranges stable and reduce the prospect of side effects.

So, if you’re alleged to be taking 30mg per day, you possibly can break that down into three

separate doses of ten milligrams each and take it with meals spread out

throughout the day. Taking an excessive amount of of this steroid at once could cause disagreeable unwanted facet effects, so it’s

best to begin out small and work your way up. I even have no way to say how my

liver perform was affected however my eyes aren’t turning yellow and im not pissing blood so so far as

i can inform my liver is ok.

This means they have to allow for regular rest periods between intense exercise periods to

forestall overtraining and damage. With Out the help of any

performance-enhancing substances like Anavar, they might additionally discover it challenging to

push their strength to new heights as they progressively attain their personal plateaus.

The picture of a bodybuilder before using Oxandrolone is one

marked predominantly by pure physique progress.

This particular person has developed his or her muscle mass

and power by way of regular exercises and strategic diet.

This allows a really excessive amount of Anadrol to stay

energetic within the bloodstream when taken orally.

Nevertheless, these results are based on excessive doses for

extreme intervals of time; thus, results for a bodybuilder

might be barely less, assuming a shorter cycle and a more cautious dose.

Anadrol is 3x more anabolic than testosterone, to place its muscle-building potential into perspective.

Another thing to keep in mind is that Dianabol has only got a short shelf life of 3-5 hours, so that you might need to

break up the 30-50mg dose across the day. This will ensure you keep optimum blood concentration ranges.

Plus taking it at meal occasions will assist to attenuate nausea or some

other stomach issues you might be more doubtless to expertise.

Stacking, Dbol’s half-life, and issues of legality

and security inform us concerning the nature of such substances.

Using Dbol in tandem with Testosterone may be effective, but it requires a nuanced understanding of dosage,

biking, and potential risks. Knowing about Dbol’s half-life can enable higher dosage

scheduling, while acknowledging its legal status can safeguard

users from potential authorized points.

However, a examine has shown that muscle and strength results could be entirely lost 12 weeks post-supplementation in sedentary older

males (13). This is a contrary scenario compared to weightlifters, who usually remain lively

following an Anavar cycle. In this similar examine, fat loss results have been largely

retained long-term. Subsequently, users may be required to continue their coaching routine to

maintain muscle and energy results, whereas reductions in adipose tissue look like long-lasting.

However, if, after a cycle, an individual discontinues coaching and overeats, fats accumulation is more doubtless to occur.

One good thing about Anavar supplementation, which isn’t evident by researching before and after photographs,

is elevated energy.

We have found HPTA dysfunction to be notably widespread in older users.

To scale back this threat, customers can decrease their saturated fat and salt consumption to enhance cholesterol

ratios and blood viscosity. Ladies taking greater

than 10 mg/day or biking Anavar past 6 weeks dramatically

increases the risk of virilization, in our expertise.

Dianabol (Methandrostenolone) has distinct effects relying on when it’s taken. Under

is a comparison of its impression on different aspects of coaching.

The above transformation is typical for a steroid-newbie, who’s doubtless used Dianabol or Testosterone.

genopharm hgh kaufen

References:

https://funnyutube.com/

**pinealxt**

pinealxt is a revolutionary supplement that promotes proper pineal gland function and energy levels to support healthy body function.

**energeia**

energeia is the first and only recipe that targets the root cause of stubborn belly fat and Deadly visceral fat.

hgh somatropin kaufen

References:

artbeninshow.afiganmey.com

**boostaro**

boostaro is a specially crafted dietary supplement for men who want to elevate their overall health and vitality.

**prostabliss**

prostabliss is a carefully developed dietary formula aimed at nurturing prostate vitality and improving urinary comfort.

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

hgh hormone kaufen

References:

http://www.udrpsearch.com

**potentstream**

potentstream is engineered to promote prostate well-being by counteracting the residue that can build up from hard-water minerals within the urinary tract.

hgh kaufen apotheke

References:

forum.issabel.org

anabolic steroids hgh

References:

best way to inject steroids (gitea3.ecloud.E3labs.net)

**hepato burn**

hepato burn is a premium nutritional formula designed to enhance liver function, boost metabolism, and support natural fat breakdown.

**hepato burn**

hepato burn is a potent, plant-based formula created to promote optimal liver performance and naturally stimulate fat-burning mechanisms.

**cellufend**

cellufend is a natural supplement developed to support balanced blood sugar levels through a blend of botanical extracts and essential nutrients.

**prodentim**

prodentim is a forward-thinking oral wellness blend crafted to nurture and maintain a balanced mouth microbiome.

**flowforce max**

flowforce max delivers a forward-thinking, plant-focused way to support prostate health—while also helping maintain everyday energy, libido, and overall vitality.

**revitag**

revitag is a daily skin-support formula created to promote a healthy complexion and visibly diminish the appearance of skin tags.

**neuro genica**

neuro genica is a dietary supplement formulated to support nerve health and ease discomfort associated with neuropathy.

**sleeplean**

sleeplean is a US-trusted, naturally focused nighttime support formula that helps your body burn fat while you rest.

best supplements for bodybuilding without side effects

References:

gitea.offends.cn

closest thing to steroids but legal

References:

git.mario-aichinger.com

hgh fragment 176-191 kaufen

References:

intensedebate.com

hgh kaufen schweiz

References:

https://matchmingle.fun/@maximilianocon

**memorylift**

memorylift is an innovative dietary formula designed to naturally nurture brain wellness and sharpen cognitive performance.

steroids pills names

References:

nelgit.nelpi.co.uk

where can i get anabolic steroids

References:

git.toad.city

The world of peptide therapy has expanded rapidly in recent years, offering athletes, bodybuilders and aging populations new tools

to enhance growth hormone release, improve recovery,

and maintain muscle mass. Among the most frequently

discussed peptides are CJC-1295 and Ipamorelin, often paired with

Sermorelin as part of a comprehensive HGH secretagogue protocol.

Understanding how these compounds interact,

what dosages work best for different goals,

and how to structure an effective regimen is essential for anyone considering incorporating them into their health

or performance plan.

CJC-1295/Ipamorelin Dosage: Crafting the Perfect Regimen

The ideal dosage schedule for CJC-1295 and Ipamorelin depends on several factors, including body weight,

training intensity, age, and whether the goal is muscle hypertrophy,

fat loss, or anti-aging benefits. A common approach involves a split injection protocol that maximizes the

natural pulsatile release of growth hormone while minimizing side effects.

A typical regimen for an individual weighing 80 kilograms might look

like this:

• CJC-1295 (modified GHRH analogue) – 100 micrograms per dose

• Ipamorelin (GHRP-6 analogue) – 50 micrograms per dose

These doses are usually administered twice daily, one injection in the morning before breakfast and another in the evening about two hours

after dinner. The injections are often split into

smaller aliquots to reduce the risk of hypoglycemia or water

retention. For instance, a single 100-microgram CJC-1295 dose can be divided into two 50-microgram sub-injections separated by

30 minutes.

The timing of these doses is crucial because growth hormone secretion follows a circadian rhythm, peaking during deep

sleep. By placing the second injection in the evening, you stimulate the body to produce

additional HGH during nighttime, which is when muscle repair and fat metabolism are most active.

Many users report increased energy levels, improved sleep quality, and faster recovery times when following this split

schedule.

Introduction to CJC-1295 and Ipamorelin

CJC-1295 is a synthetic analogue of growth hormone-releasing hormone (GHRH).

It binds to the GHRH receptor on pituitary cells, stimulating the secretion of endogenous growth hormone.

The key advantage of CJC-1295 over natural GHRH is its extended half-life; it remains active in circulation for up to 24 hours due to a special attachment that prevents rapid degradation. This prolongation allows for less frequent dosing

while maintaining consistent HGH stimulation.

Ipamorelin, on the other hand, belongs to the

class of growth hormone-releasing peptides (GHRPs).

It mimics ghrelin, a stomach peptide that signals hunger and stimulates growth hormone release

via the GHSR-1a receptor. Ipamorelin is distinguished

by its selectivity: it releases growth hormone without significantly affecting cortisol or prolactin levels, reducing the likelihood of unwanted side effects such as increased appetite or water retention.

The combination of CJC-1295 and Ipamorelin harnesses two complementary pathways to drive

HGH production. While CJC-1295 activates GHRH receptors on a larger scale, Ipamorelin provides a fine-tuned, receptor-specific boost that

can be timed precisely with meals or training sessions. The synergy between these

peptides results in a more robust and sustained increase in growth hormone levels compared to either peptide alone.

What are CJC-1295 and Ipamorelin?

CJC-1295 is engineered from the naturally occurring GHRH but modified to resist enzymatic

breakdown. Its structure includes an amide group at the

C-terminus that protects it from peptidases, and a small peptide sequence that prolongs its action in the bloodstream.

When injected subcutaneously, CJC-1295 travels through the lymphatics, reaching

the pituitary gland where it binds to receptors and triggers the release of growth hormone.

Ipamorelin is a pentapeptide with the sequence Gln–Trp–His–Gly–Leu.

It was designed to be a potent, selective agonist for the ghrelin receptor.

Because of its small size, Ipamorelin can be administered in very low doses (50-200 micrograms) yet still produce measurable increases in HGH secretion. Its selectivity also means

it does not significantly influence other hormones such as prolactin or ACTH, which is why many users

find it to be a “clean” option for growth hormone stimulation.

When these peptides are used together, they provide

a two-pronged attack on the hormonal system: CJC-1295 ensures a steady baseline of HGH release throughout the day,

while Ipamorelin delivers a targeted spike that can coincide with training or recovery periods.

This dual approach is particularly attractive for athletes looking to

maximize muscle protein synthesis and fat oxidation without the side effects

associated with higher doses of traditional growth hormone therapy.

Practical Considerations for Dosing

Weight-Based Adjustments – While 100 micrograms of CJC-1295

and 50 micrograms of Ipamorelin are common starting points, users may need to adjust based on body mass.

A lighter individual might find a 75/25 microgram split sufficient, whereas heavier individuals could benefit from

up to 150/75 micrograms per dose.

Training Load – Those engaging in high-intensity resistance training or long endurance sessions can increase

Ipamorelin dosage slightly (up to 100 micrograms) to enhance post-exercise HGH release.

This can help accelerate muscle repair and reduce

soreness.

Sleep Quality – Because growth hormone peaks during deep sleep, maintaining a

consistent bedtime routine is essential. Users often report better REM

sleep when using CJC-1295/Ipamorelin because of the hormone’s influence

on sleep architecture.

Cycle Length – A typical cycle lasts 8 to

12 weeks. After completing a cycle, many practitioners recommend a break

of at least 2 weeks dianabol before and after photos starting

another to allow the body’s endocrine system to recalibrate.

Monitoring and Side Effects

Blood tests measuring IGF-1 levels can provide an indirect assessment

of growth hormone activity; elevated IGF-1 indicates effective stimulation. Users should also

monitor for signs of water retention, increased appetite, or mild

headaches, which may signal excessive HGH production. Adjusting the dose downward or spacing

injections further apart often mitigates these symptoms.

In conclusion, crafting a precise CJC-1295 and Ipamorelin regimen involves

balancing dosage, timing, and individual physiology to maximize growth hormone release

while minimizing adverse effects. By adhering to a split injection protocol that respects circadian rhythms and

training demands, users can harness the full potential of these peptides for muscle

growth, fat loss, or anti-aging benefits.

arnolds steroid cycle

References:

http://www.e-vinil.ro

how long for deca to kick in

References:

git.rongxin.tech

how long does prednisone withdrawal symptoms last

References:

https://gitlab.jmarinecloud.com/ken91p28175833

meditech steroids

References:

appleradish.org

safe alternatives to steroids

References:

https://niqnok.com/

onlineroids reviews

References:

gitea.svc.obaa.cloud

A PCT, together with a SERM such as clomiphene, can help shorten this restoration interval.

Dianabol is a C-17 alpha-alkylated steroid, and thus liver toxicity is

for certain, basically increasing the workload on the organ. We have discovered that

supplementation with TUDCA (tauroursodeoxycholic acid) during Dianabol cycles minimizes hepatic stress,

decreasing ALT (alanine aminotransferase) and AST (aspartate aminotransferase) enzymes.

It is fairly frequent for underground labs to order uncooked product from

those nations and package deal it themselves. The greatest Steroid customers are the Middle East, followed by South

America, Europe, and North America.

Anavar, or Oxandrolone, was first developed in the Nineteen Sixties by Searle Laboratories.

It was initially used to deal with quite a lot of medical conditions, together with weight reduction because of

surgery, chronic infection, and trauma. Anavar is known for its mild nature and is usually thought-about one

of many safer steroids obtainable. Clenbuterol is commonly stacked with chopping steroids for accelerated fat loss.

Dosages can increase up to 120–160 mcg per day; nevertheless,

girls should monitor how they feel and frequently verify their

blood pressure and heart rate to ensure they don’t become excessively elevated.

Nonetheless, there is evidence to recommend that

clenbuterol has some anabolic properties, with its ability to increase skeletal muscle in animals (4).

We have had girls declare that Clenbuterol does help them construct

muscle and increase energy, whereas others notice little (if any) improvement.

A ketamine spinoff, esketamine, is approved by the FDA for treatment-resistant despair

in adults. Hydrocodone is misused when it is

taken in a means or dose that’s different than prescribed, taken with no prescription, or taken with other drugs to

boost intoxicating results. GHB and comparable substances

may be misused for their euphoric and sedative results. GHB has been used to

commit sexual assaults because of its sturdy sedation results.

Most are categorized as analysis chemical substances,

missing FDA approval and long-term Gynecomastia pill safety data.

Sourcing, dosing, and legality range extensively, and aggressive athletes should consider anti-doping rules.

Consulting a educated healthcare supplier is not just recommended —

it’s critical.

Healthcare suppliers prescribe them for sure circumstances, corresponding to male

hypogonadism and certain types of breast most cancers.

Turinabol, a by-product of Dianabol, is an anabolic steroid identified for its unique capability to supply steady muscle

positive aspects and energy improvements with minimal water retention. It’s favored for its balanced

anabolic and androgenic results, making it a popular choice for athletes looking for efficiency enhancement without extreme bulk.

For those in search of efficiency enhancement with

out the risks, authorized alternatives similar to SARMs (Selective Androgen Receptor Modulators) and pure dietary supplements

provide safer choices. These merchandise goal to

mimic anabolic results without severe side effects.

SARMs selectively target androgen receptors, offering comparable benefits with fewer side effects.

However they still carry dangers and aren’t accredited

for human use by the FDA. Anabolic steroids are classified as controlled substances in many

nations as a result of their potential for misuse and abuse.

In the Usa, they’re categorized as Schedule III drugs underneath the Controlled

Substances Act. Bodybuilders usually face injuries that

interrupt training and sluggish progress.

Stacking steroids comes with larger potential results

but also with increased risks, and these additionally need to be thought of.

There are presently no FDA-approved drugs to deal with sedative, hypnotic or anxiolytic use problems.

There are behavioral treatments for substance use issues, corresponding to cognitive behavioral remedy and contingency management.

There are presently no FDA-approved drugs to deal with methamphetamine or different

stimulant use issues. There are currently no FDA-approved medicines to treat MDMA-related substance

use problems. There are presently no FDA-approved

medicines to treat a loperamide-related substance use dysfunction. There are presently no FDA-approved medications to deal with

ketamine use dysfunction.

Anavar-only 6-8 weeks cycles might be between 40mg and 100mg every day dosing, with less suppression than Dianabol.

Anavar is superb for fat-burning and drying out the physique, though, so if that’s your

goal, it’s the go-to compound. However, that would be more of a sophisticated technique that you’d desire

a specific purpose to follow.

One phrase that rings true more than ever here is the phrase ‘The poison is in the does”. No one goes to run into cholesterol issues using a wee 150mg of Testosterone per week, but bump that up tenfold and you’re definitely in for a tough time. The prospect of fully safe steroid use remains elusive, as acknowledged by the article. Whereas arguments may be made for the relative security of decrease doses, a nuanced strategy is necessary. Aromatization, or the conversion of steroids into estrogen, is an enormous concern.

In contrast with the antagonistic effect on LDL- and HDL-cholesterol, AAS seem to

exert a impartial or favorable effect on lipoprotein (a) (Lp(a)).

Elevated Lp(a) levels are thought of a longtime causal risk factor for CVD (140).

In a double-blind trial, nandrolone decanoate (200 mg weekly) for 8 weeks decreased Lp(a) in contrast with baseline, however not compared with placebo,

in a bunch of bodybuilders (124).

The baseline questionnaire comprised standardized measures (see Desk 1) and

was used to collect data that may facilitate analysis of the replication of the

Athletes Studying and Coaching to Avoid Steroids [ATLAS] program.

Subsequently, the questionnaire included measures equivalent to those used in the authentic ATLAS analysis analysis.

Additional measures have been used in the analysis trial (Reference blinded

for review) however are not reported right here.

A 2019 study by the Nationwide Drug and Alcohol Research Centre (NDARC)

discovered that 1.4% of Australians aged 14 and over had used steroids up to now yr.

Yes, SARMs can show up on drug checks, significantly those designed for anti-doping purposes in sports activities.

And it’s never, ever price it to give up long run well being for

short term positive aspects. Right Here everyone can profitably and

safely purchase steroids in Australia to enhance athletic performance.

Some people will cease taking steroids with out taking any additional medications.

Yes, TRT is legal in Australia to sufferers which are recognized

with low testosterone through a blood test. We only prescribe testosterone replacement remedy to sufferers who genuinely need it

– confirmed by low testosterone ranges in a blood test and experiencing a decrease high quality

of life from signs. These substances are often sought

for his or her muscle-building and performance-enhancing results however are unlawful to own and not utilizing a

legitimate medical prescription. For those that are excited

about using authorized steroids, you will need to

achieve this responsibly. Consulting with a healthcare skilled may help to guarantee that the product is suitable for individual needs and is being utilized in a protected

and effective method.

Women handled with testosterone for breast cancer require monitoring for indicators of virilization.

Dromostanolone is a synthetic anabolic steroid with anti-estrogenic properties and is 5 instances more potent than methyltestosterone, which is usually used illegally by bodybuilders

to organize for competitors. Dromostanolone increases the retention of nitrogen, phosphorus, and potassium, leading to increased protein anabolism and

a decrease within the catabolism of amino acids, leading to

a rise in the density and hardness of muscle.

Accredited coaching actions, evidence-based clinical resources and finest practice guidelines.

MensLine Australia is a telephone and online counselling service

for men with emotional well being and relationship considerations.

Individuals can turn into depending on steroids, especially

when they’re relied on for confidence and vanity.

By choosing a good supplier like Gearmaniac, you can ensure that you’re getting genuine, high-quality merchandise delivered

discreetly and securely to your doorstep.

Say goodbye to uncertainties and belief Gearmaniac for all of your

steroid wants in Australia. Are you looking to improve your physique and performance with steroids in Australia?

With the rising popularity of bodybuilding and health culture,

discovering dependable sources to purchase steroids online has turn into essential.

In this comprehensive guide, we’ll explore

every little thing you have to find out about buying steroids in Australia,

together with authorized concerns, trusted sources, and top steroid brands.

Regardless Of these regulations, many individuals seek

various sources to purchase anabolic steroids, often by way of on-line suppliers.

Anabolic steroids are broadly sought after by athletes and fitness fanatics

in Australia trying to enhance performance, construct muscle,

and achieve their health targets. Whereas the subject could

be controversial, understanding tips on how to

navigate this space safely and responsibly is essential for anyone contemplating their

use. “There’s fairly a big on-line black marketplace for steroids … which come with plenty of dangers. That’s true for any drug, but very true when people don’t perceive the dangers of utilizing steroids [generally],” she

mentioned.

Hence, any athlete caught using SARMS can face critical penalties, including disqualification and suspension. However, you have to keep

in mind that all steroids intervene with the endocrine system.

So dough esters are susceptible to aromatization, which might trigger the event of estrogenic unwanted aspect effects.

References:

PedsElite

In such circumstances, the purpose of high-dose Winstrol is sort of for contest preparation, with outcomes coming on fast and

powerful in the two or so weeks earlier than the competition. 100mg

per day of Winstrol is a high-end dose that comes with elevated risk to the liver and certain hair loss/acne if you’re genetically inclined.

If you select to incorporate anabolic steroids into your bodybuilding pursuits, understanding tips on how to

get probably the most out of both orals and injectables in a responsible means is key to

long-term progress and health. As with all performance enhancers, schooling and self-awareness are essential.

Anavar, in distinction to the other oral steroids, actually locations higher stress on the

kidneys than on the liver. While you can count on a rise in liver enzymes whereas utilizing Anavar, for most people, this will be quite delicate and may

return to normal when you cease utilizing the steroid.

Winstrol is likely to cause virilization results in girls,

together with voice hoarseness30, zits, changes in menstrual intervals, and growth of facial hair.

Females would want to make use of very low doses of Winstrol to avoid these

effects, in the 4mg to 10mg every day range.

Nonetheless, what Winstrol can do that has a flow-on effect on the muscle tissue is increase strength, and that is the first benefit most customers will start noticing inside a short time of starting Winstrol.

Clen will substantially increase your metabolism,

ramping up fat loss. It acts as a stimulant, so potential unwanted effects will have an result on everyone in one other way – put together to alter the dose if required and monitor your blood strain throughout the cycle.

The amount of weight loss will rely on your present weight and how onerous you’re dieting and coaching –

shedding 2-4lbs of body fats per week is an achievable goal with this cycle.

It is strongly beneficial that exogenous testosterone be used by men on this cycle to

combat the effects of suppression.

When planning a steroid cycle, one of the important choices is whether or not to make

use of oral or injectable compounds. So when utilizing this steroid in a cycle on its own, you usually won’t

see any important side effects. Testosterone suppression just isn’t extreme, and ranges recuperate and normalize inside a couple of weeks (for most users).

So, customers build muscle while shedding weight, but it also has powerful

lipolytic properties, making Anavar knowledgeable fats burner.

If you already suffer from hypertension, it is strongly suggested

that you don’t use this steroid, or some other steroids

are known to extend blood pressure, with out first seeking out medical advice.

We, due to this fact, can’t condone using anabolic steroids

with a transparent conscience, nor will we suggest their

use.

Anabolic-androgenic steroids (AAS) differ from other unlawful medicine in that they don’t

seem to be taken for a excessive or different emotional effects.

They are taken to enhance physical attributes, muscle mass, and improve bodily efficiency.

Trenbolone is a potent anabolic steroid that’s extremely efficient for

muscle progress and energy features. It is used by experienced athletes and bodybuilders

due to its highly effective results.

There just isn’t much distinction in Anavar dosage

for bodybuilding functions whether or not you’re a person or woman. For instance, you might take Anavar for eight weeks and then take a break for four weeks.

This will assist to forestall your physique from turning into tolerant to the

medicine. If you may be figuring out two

instances per week – we recommend beginning with 50mg of Anavar per

day. For occasion, if you’re figuring out four occasions per week – we suggest beginning

with 20mg of Anavar per day. If you are working out greater than three times per week, we suggest starting at the

lower end of the dosage vary.

Anavar (oxandrolone) is a man-made steroid, much like the naturally occurring steroid testosterone.

The mixture considerably enhances power and muscle fullness.

Top pharmaceutical manufacturers include Ciba (discontinued),

Alpha Pharma, and British Dragon. Keep Away From “D-Bal” legal alternatives – they

don’t comprise actual Dianabol. Deca Durabolin additionally solely impacts HDL/LDL cholesterol to a gentle diploma and poses no hepatotoxicity,

being an injectable steroid like testosterone. In our

expertise, the least toxic stack for mass can be testosterone

and Deca Durabolin. Testosterone is often used as

the primary steroid cycle, which usually produces 20–25 lbs in mass.

Nonetheless, SERM’s, whereas not all the time as effective will actually promote healthier cholesterol levels as a result of their estrogenic like activity in the liver.

SERMs negate the negative suggestions on the pituitary exerted by estrogens, and aromatase inhibitors impede the

formation of those estrogens. Both classes of compounds indeed increase testosterone ranges in males with hypogonadism

as a outcome of varied causes. Testosterone ranges lower again after

the agents are discontinued, implying that they do not solve the underlying reason for hypogonadism.

As such, it stays to be seen whether they present efficacy in the case of AAS-induced hypogonadism, as PCT is usually performed for a few weeks.

Previous medical research have found that virilization was minimal in females18 who obtained a minimal of

50mg daily for a minimal of three months. Virilization is all the time

possible at any dose, and females must be in search of voice changes or physique hair progress.

Due to Anadrol’s potency, we don’t stray far from those medical doses.

Liver toxicity, water retention, and ldl cholesterol

impacts mean that very excessive doses of this harsh steroid ought to be averted even by experienced users.

Everybody will differ, however in most circumstances, you’ll profit

significantly from a dosage of 100mg per day while preserving to

a cycle of 4-6 weeks most.

Contemplating that the typical training routine of an AAS person entails no much less

than three to 6 periods per week of at least one hour, that is sure to impact these markers.

Due To This Fact, ideally, measurement must be carried out after at least 1

week of abstinence of train. GGT and bilirubin ranges in serum don’t appear to increase

in response to exercise (111).

References:

Core conditioning exercises

If you are feeling like steroids are essential that will help you achieve your

fitness or look targets, you want to discuss to your physician. If you’re already using steroids, your physician might help you to stop

utilizing them safely. We additionally need

to see peer‑led help by way of trusted packages to educate individuals who use steroids around the dangers.

The programs must be based mostly in real evidence, and developed

by people with lived experience of steroid use, in partnership with researchers

and clinicians. For example, one product labelled as testosterone enanthate (200mg/mL) contained 159mg/mL of

trenbolone (a potent sort of steroid) and no detectable testosterone.

If you have a respectable prescription, you can pick up the medication at a pharmacy, and it’s covered by the same rules that apply to different S8 drugs like morphine.

Nonetheless, there’s also a separate offence for ‘trafficking’ in a managed substance, with a maximum

penalty of 21 years imprisonment. They are illegal to possess, use, or provide them, and not utilizing a

legitimate prescription or authorisation. If the possession was for the aim of trafficking,

it instead carries a maximum penalty of 5 years imprisonment and/or a $76,924 fine (400 penalty

units x present worth of $192.31). In Victoria, ‘anabolic and

androgenic steroidal agents’ are thought of

a drug of dependence.

The maximum penalty for this offence is imprisonment for 5

years or 1,000 penalty units or both. Here’s a secure, fast approach to discover

the real site, spot red flags, and perceive the authorized and medical dangers in Australia (2025).

If you actually need steroids for a medical cause,

one of the best route is to speak to a GP or specialist. They can assess whether a steroid is acceptable,

write a prescription, and refer you to a regulated pharmacy.

Telehealth services have turn into more frequent, and plenty of respected platforms now provide

video consultations that may result in a reliable prescription, supplied you meet the medical standards.

Seek The Guidance Of your physician about tapering the

dose all the way down to keep away from withdrawal signs.

It is an offence to own anabolic steroids, with a most penalty

of 14 years imprisonment if this entails a industrial

quantity. The similar penalty is applicable to deliberately supplying or participating in the

supply of anabolic steroids to another person. In Victoria, anabolic steroids are categorised as medicine of dependence under the Medication,

Poisons and Controlled Substances Act 1981 (Vic) (DPCSA).

The excessive physical demands of the game, mixed with its competitive nature, have generally led gamers to turn to

performance-enhancing medication (PEDs), including anabolic

steroids, to realize an edge. Whereas rugby has strong anti-doping measures in place,

cases of steroid use have tarnished the sport’s

popularity and highlighted ongoing challenges. Whereas Canada does not carry

harsh possession laws, there are international locations that carry no possession legal guidelines per

say; in-fact, you won’t even want a prescription however you should make your

buy from the pharmacy. Many European nations carry such legal guidelines, and the United Kingdom is the

prime example.

The World Anti-Doping Company (WADA) oversees anti-doping rules globally, banning all anabolic steroids

in competitive sports. Athletes discovered utilizing steroids

face suspensions, bans, and reputational damage, no

matter local laws. As we look to the longer term, the regulation of anabolic steroids is more doubtless to remain a posh issue.

Online gross sales have made it easier for people to

buy steroids with out prescriptions, often from countries with lax rules or enforcement.

This underground market poses extra dangers, as many black-market steroids are counterfeit or contaminated, growing the well being dangers for users.

As their use spread past medical contexts and into aggressive sports activities

and leisure bodybuilding, governments acknowledged the want to regulate them.

This push for regulation was fueled by high-profile scandals in professional sports activities,

which exposed the extent of steroid abuse. At Present, the authorized approach to anabolic steroids ranges from complete prohibition to managed medical use, relying on the region. There are few countries where anabolic

steroids are still authorized and out there

to be used. Anabolic steroids are not explicitly listed as

a controlled substance within the United Arab Emirates, however they are

nonetheless illegal to possess and use without a legitimate prescription.

Furthermore, it could restrict prospects for skilled progress, result in job loss, or

both. The first thing a legal defence lawyer does is undergo the case

particulars. This evaluation consists of wanting at the specifics of the arrest, the data gathered, and the conduct of the regulation enforcement officers.

The legality of the search and seizure, the source of the proof,

or the reason for the possession can all be contested as a part of this technique.

It’s essential to keep in thoughts that each state and territory in Australia has

primary authority over legal regulation. Subsequently, carrying

steroids can end result in various penalties relying on the jurisdiction where the incident occurred.

Nonetheless, there are some commonalities within the penalties in varied states.

The affordable costs of the buy steroids Australia on the positioning are for real products, and you’ll contact our customer

service workers with any questions through the Contact Us section of

our website. Before buying any drugs at our specialized sports activities pharmacology retailer, we give you a

free full consultation. Tech/Business refers

again to the technology and business surroundings, including

its innovation capability, entrepreneurship, and competitiveness.

This class contains metrics corresponding to research and improvement

spending, patent applications, ease of doing enterprise, and access to finance.

References:

Referenzen und Quellen zu Kreatin

DHT has been proven to bind avidly to receptors in tissues, such as skin, scalp,

and prostate, and to exert 3-4 instances the androgenic impact

of testosterone. Thus, the primary hormone mediating the androgenic effects of testosterone is actually the 5-alpha decreased DHT.

Testosterone exercise is mediated by way of

an androgen receptor that’s current in varied tissues all through the human physique.

Testosterone binds to an intracellular receptor found

in the cytosol of cells, forming a receptor

complex that migrates into the nucleus, where it binds to specific

deoxyribonucleic acid (DNA) segments.

Statins may cause muscle ache in a small proportion of customers (152), however this

aspect impact may occur extra regularly

in those that interact in regular intense train (153). For this

group of patients, an professional panel recommends the

use of hydrophilic statins (rosuvastatin and pravastatin) at a low-to-moderate dose, as

hydrophilic statins are regarded as extra hepatoselective (153).

If the statin is not tolerated, it is advisable to

vary to a lipophilic statin (e.g. simvastatin or

atorvastatin), reduce the dose, or attempt an alternate-day regimen (154).

We assure that all steroids bought from us are high quality

and dependable. Thanks to us you should purchase anabolic

steroids or auxiliary preparation and ensure of its

quality. GoAnabolics.com does not in any method name for the

utilization of anabolic steroids, but only presents high quality gear for

individuals who determined to make use of them. Winstrol can be troublesome for

the joints as a end result of its drying-out effects, offering less cushion and lubrication. Thus, Winstrol will

not be an acceptable steroid for aged bodybuilders who regularly lift heavy weights, as our older sufferers have reported aches or severe pain following Winstrol cycles.

Winstrol may also cause significant cardiovascular pressure

because of substantial increases in LDL ldl cholesterol and decreases in HDL.

In some customers, we see this causing a flushed appearance to the pores and

skin, signifying a spike in blood pressure and thus a better physique temperature.

Nonprescription doses are often 10 to one hundred times greater than the doses healthcare providers prescribe to deal with medical situations.

This is why the unwanted aspect effects are normally extra extreme

than the unwanted effects of prescribed anabolic steroid use.

Misuse of anabolic steroids can cause quite lots of unwanted side

effects starting from mild to harmful and even life-threatening.

Most unwanted effects are reversible if you cease taking the medicine, however others could

also be permanent. Whereas tablet testing is now widespread at

festivals for medicine similar to ecstasy, testing anabolic steroids requires more

complicated chemical evaluation that cannot be performed on-site.

Current steroid testing relies on superior laboratory methods, which limits availability principally to

specialised analysis programs similar to those in Australia and Switzerland.

Gen Kanayama, MD, PhD, has authored over 20 research concerning the effects of anabolic steroids.

BodyLogicMD affiliated physicians are essentially the most extremely educated

in Effective natural muscle boosters bioidentical

hormone substitute remedy with integrated fitness and diet applications which they’ve been offering to

their sufferers since 2003. Our sufferers are

highly and constantly glad with the companies they receive.

You can rest assured that if you go to a BodyLogicMD affiliated doctor,

you’ll get the care you deserve. Testosterone is the bioidentical anabolic androgen we endogenously produce and rely on, and is most of

the time probably the most clever hormone to use

for a primary cycle. The 19-Nors are essentially the most suppressive family of the

anabolic steroid household tree, and can maintain your HPTA suppressed even at

minuscule hint amounts. In addition, it lowers corticosterone

and cortisol levels, while concurrently inhibiting cortisol from

binding to skeletal muscle glucocorticoid receptors

[R, R, R]. There are exceptions to the rule in each class of the

anabolic steroid household tree, and the DHT derivatives are

no completely different as they have Anadrol.

For a listing of coated advantages, please discuss with your Proof of Protection or Summary Plan Description. For beneficial remedies,

please seek the advice of together with your well being care supplier.

Let’s get into what steroids are, what they’re used for (both legally and

illegally), and tips on how to find some safe alternatives to steroids that’ll give you the similar

results. Whatever your objectives, it’s the wrestle to get there that’s most rewarding.

It’s virtually as if life itself is inviting us to embrace difficulty—not as punishment however as a

design function. Natalie Watkins is a medical writer and educator specializing in mental health.

A person who is using anabolic steroids could flip to different supplementary medication. As Soon As the receptors are stimulated, a domino

impact of metabolic reactions takes place as the drug instructs the

body to increase muscle tissue manufacturing. Certain unwanted effects of

anabolic steroids could additionally be everlasting, similar to organ damage and stretch marks on your pores and skin. Furthermore, steroids won’t make you “healthy”

when they’re misused in such ways. It’s important to seek medical help in case you

are taking anabolic steroids as prescribed and are experiencing any concerning

unwanted side effects. As elite athletes are caught dishonest through

the use of anabolic steroids, perhaps their perception as positive position fashions will

fade and the use of steroids lower. Elevated pressure to test athletes

at younger ages might decrease using steroids as properly.

Depression has also been linked to steroid use, and athletes who use performance-enhancing steroids are more doubtless to attempt

suicide than athletes who do not use them. Moreover, athletes who

use a needle to inject steroids might have ache on the injection site

and risk growing an an infection. People ought to seek the guidance of with medical professionals earlier than contemplating TRT.

The mechanism mediating an AAS-induced improve in blood strain is

tough to evaluate, and most proof comes from in vitro

and animal experiments. AAS are predominantly bioinactivated in the liver,

but also in the kidneys and various different androgen-sensitive tissues (25).

In basic, section I metabolism mainly involves reduction at carbons 3 and 5 of the

A-ring and oxidation of the hydroxyl group at carbon 17 of the

D-ring of the steroid nucleus (24).

On the other hand, legal steroid alternatives are thought of safer options for these trying to enhance their physical

performance and build muscle mass. They work by utilizing pure ingredients to stimulate the

physique’s hormone production and metabolic processes, thereby encouraging muscle growth and fats

loss. Additionally, authorized steroid alternate options

are easily accessible, as they can be bought legally and not utilizing a prescription. Hunter Test is a premium authorized steroid designed

for these who are in search of an additional edge in building muscle mass and enhancing total efficiency.

Made from pure constituents, this highly effective complement offers a protected various to artificial anabolic steroids, eliminating the

chance of harmful side effects. With its unique mix of potent ingredients, Hunter Test aids in bettering stamina, elevating testosterone ranges, and increasing

lean muscle mass. Usually the consequence following any

prohibition and criminalization of a substance generates an enormous flourishing and

expansion of the black market trade of anabolic steroids.

You can get away with stacking orals together – for instance, Anadrol and Winstrol.

I nonetheless largely favor injectables to keep away from hepatotoxicity, Anavar

being one exception. However should you don’t like injecting, then orals are nonetheless a superbly viable choice.

Here’s just one instance of a standard 12-week cycle, including ideas for newbie, average, and heavy

customers. It begins to turn out to be attainable to make use of HCG throughout a cycle of this length, but

most guys won’t want or wish to use it for thus

lengthy and as an alternative use HCG in course of the tip of the cycle.

By enhancing the effectivity of how your body uses nutrients

from foods (mostly carbs, proteins, and fats), each calorie you take in is used to its full potential.

None of the experts at Legacy Pharma have skilled this

personally. Nonetheless, we don’t discriminate against anyone’s private experiences.

Like all areas of drugs, advances in performance drug testing are continuously ongoing and beneath analysis.

This brings about new strategies that may or could not

become commonplace and widespread in drug testing worldwide.

You can’t assume one 12 months to the subsequent

that the same avoidance strategies will work. Some current developments

in anti-doping testing that labs have developed embody gene doping exams, retroactive

liquid testing, and long-term metabolites.

Browse our curated listing of the most effective and most

trusted steroid sources online. Each website featured here offers legitimate anabolic steroids, fat burners, and muscle-building compounds—backed by user evaluations,

confirmed outcomes, and worldwide or USA domestic transport.

Whether Or Not you’re planning a full anabolic cycle or want reliable post-cycle remedy (PCT), these verified suppliers are selected to serve the bodybuilding and

health group with high-quality products at competitive costs.

Safe your buy of premium anabolic steroids conveniently online within the USA, ensuring safety and quality.

Our online pharmacy stands out as a trusted provider, catering to these in search of

to take care of vitality and muscle power. Explore a various range of anabolic steroids obtainable on the market

via our platform.

But… When it comes to female PED use, it’s the discount in breast measurement that you simply need to

be aware of as a aspect impact. Whereas this facet impact

isn’t more doubtless to develop as quickly as voice modifications

or hair growth, it’s a reminder of why preserving

lower doses and using milder compounds is important. As you can see, though, nearly all anabolic steroid

users will persist with injecting their gear by way of the muscle whereas leaving subcutaneous injections for these additional compounds which are sometimes used.

As we age our pure testosterone ranges start to quickly decline; particularly as we reach the age of thirty.

If you’ve noticed a lack of muscle mass, extra body-fat

even with the same diet and train program, lethargy or

decreased libido, you may qualify for a prescription. In some cases those

younger than the age of thirty will qualify however thirty is usually the age many physicians

use as the beginning point. For the usage and dosage of anabolic steroids, please check

with the skilled guidance offered by the unique pharmaceutical company.

Mostly, we’ll do frontloading when using slower-acting steroids which have

a longer half-life, like some of the in style testosterone esters, together with Testosterone Enanthate and Testosterone Cypionate.

Frontloading is a perfect strategy as a outcome of these steroids can take a few weeks to begin delivering effects.

Nevertheless, the process of esterification (attachment of an ester) is maybe

the most important think about a steroid’s half-life.

In those receiving 1-androsterone, serum creatinine ranges increased significantly

from 97.3 μmol/L (1.1 mg/dL) to 115.zero μmol/L (1.three mg/dL).

As with different side effects, some AAS users self-medicate to mitigate this unfavorable shift in lipid profile.

This consists of each dietary supplements, similar to niacin, pink yeast rice extract and

berberine, but in addition prescription treatment similar to statins.

Prioritizing compliance with laws is important for a lawful and safe acquisition course of.

Some athletes could appear to get an edge from performance-enhancing medication. Some drugmakers and exercise magazines declare that

andro products assist athletes train more durable and get well faster.

You should have regular appointments together with your healthcare supplier

when taking an anabolic steroid to evaluate how properly it’s

working.

Bodybuilders typically take HGH in exogenous kind to extend HGH

manufacturing, growing muscle mass and fat

loss. Though not essentially the most highly effective of steroids, Deca is usually used by bodybuilders to reinforce the features from other

bulking steroids. The above unwanted aspect effects, plus the fact that Sustanon 250 is an injectable steroid,

may find yourself in some folks avoiding this anabolic

steroid.

References:

Réponses aux questions courantes sur le clenbutérol

However, there stays scant proof in relation to efficient coverage and practice throughout

the subject. Whereas we now have a higher understanding of the environmental influences and danger elements to be used [17, 60,61,62], there are few sturdy findings to

assist the efficient prevention of AAS use. Little progress

has been made in answering the fundamental questions of how will we make AAS much

less engaging and how will we make these medicine much less accessible to those

susceptible to initiating use [63,64,sixty five,66]. Externalizing behavior, consideration problems and ADHD have been among the ASEBA scales with the largest differences between AAS and WLC groups.

These findings are consistent with earlier findings of elevated ADHD signs and

history of conduct disorder among men using AAS [50, 51].

In addition, girls who use AAS usually use different substances,

and exhibit different health-compromising behaviors, which can partially clarify the connection between AAS use

and a focus issues on this study [44, fifty three, 54].

In horses, for example, anabolic steroids may cause liver harm

and weakening of the tendons and can end result in decreased testis dimension and sperm production in stallions and altered reproductive cycling in mares.

Abuse of anabolic androgenic steroids (AAS) is highly prevalent among

male recreational athletes. The objective of this examine was

to research the influence of AAS abuse on reproductive hormone levels and

signs suggestive of hypogonadism in current and former

AAS abusers. Androgens, antiandrogens, and anabolic steroids drugs are natural and artificial types

of testicular hormones. They are used to deal with hypogonadism, delayed male puberty, and a

few types of feminine breast most cancers.

Comparable outcomes had been reported by Krieg et al.

who noticed a decreased Em/Am ratio on the basal a part

of the interventricular septum in a small group of AAS-using

bodybuilders in contrast with steroid-free power athletes and sedentary

controls (216). Em/Am ratio is the ratio between the rate of the myocardial wall during early diastole

(Em) and late diastole (Am), and a decrease on this ratio is indicative of diastolic dysfunction. LDL-cholesterol

is generally unaffected by injectable AAS such as testosterone enanthate (up

to 600 mg weekly) (15, 34, 37, 119–121) and nandrolone decanoate (up to 200 mg weekly) (123, 124), with one trial

showing a 16% lower after 6 weeks of 200 mg testosterone enanthate weekly (118).

Oral AAS again show unfavorable changes, constantly growing LDL-cholesterol (38, 118, 121, a

hundred twenty five, 126). In the HAARLEM study, LDL-cholesterol increased by zero.45 mmol/L compared with baseline (46).

Erythrocytosis, or polycythemia, a rise in blood hematocrit or hemoglobin ranges, is a common aspect impact of AAS use,

even on substitute dosages. It is essentially the most frequent adverse event in older men receiving testosterone substitute remedy (TRT) (40).

Mesterolone has very low to no oestrogenic activity and shows only

slight hepatotoxicity. The introduction of a methyl group in position 1α leads to an increased oral

exercise. Oral exercise can also be achieved by the introduction of the 17α-alkyl group (as seen in methyltestosterone).

This modification results in lowered metabolism in the

liver and increased bioavailability, however hepatotoxicity is also increased [17,18].

Methandriol (9, Determine 3) is out there in each oral and injectable

forms as dipropionate, propionate, and bisenanthoyl acetate

esters.

The effects of SERMs haven’t been studied extensively in males

and long-term results are unknown. In males, aromatisation of testosterone to oestradiol is important to succeed in and

keep bone mass, and the long-term results of SERM administration on bone well being in hypo- or eugonadal males haven’t been established.

Additionally, there is proof that sexual perform in men is dependent upon the combined effects of androgens and oestrogens (21).

Although detrimental results of SERMs on sexual operate in men haven’t

been reported in small and short-term studies (22),

these results can’t be excluded.

Ongoing AAS abuse causes dramatic will increase in plasma androgen levels that

finally facilitate severe hypothalamic-pituitary-gonadal (HPG)-axis suppression as a result of negative feedback mechanisms involving testosterone and its metabolites [5].

HPG-axis inhibition may cause long-lasting spermatogenesis inhibition and reductions in biomarkers of Sertoli-cell perform, anti-Müllerian hormone (AMH) and

inhibin B. Nonetheless, information concerning the impact of AAS abuse on these reproductive

hormones is very restricted [6, 7].

Another chaperone called p23 stabilizes the aporeceptor advanced by

blocking Hsp90 within the ATP-bound substrate conformation. Co-chaperones using tetratricopeptide repeat motifs are

essential for docking of the Hsp90. As an adjunct, different chaperones,

called Hsp40 and Hsp70 and an organizing protein known as Hop (heat-shock organizing protein) are necessary within the meeting of the steroid receptor–Hsp90 complex.

Picard (2006) gives a clear overview of molecular chaperones

and cofactors that are related to steroid receptor motion. Phosphorylation of the receptors is also essential

in regulation of receptor function (Weigel and Moore, 2007).

According to latest information, 20% of sufferers who had been being treated for symptomatic hypogonadism

had previously used AASs.

The combination of bodily exercise and prolonged/chronic or earlier misuse of AASs leads to a predisposition to completely different patterns of myocardial harm and sudden cardiac

dying [35]. Chemico-toxicological analysis is a vital tool to assess the hyperlink between sudden cardiac dying and AAS abuse [38].

Post-mortem plays a pivotal position within the study of AAS opposed effects and organ injury associated to their use/abuse.

Furthermore, post-mortem research could present helpful info concerning the pathophysiology of the consequences of AAS long-term

administration, subsequently autopsy follow

must be carried out in suspected AASs-related deaths.

Likewise, dutasteride had no impact on hemoglobin levels in contrast with placebo when used at the

facet of graded doses of testosterone enanthate up to 600 mg

weekly (23). Long-term use of anabolic steroids can result in everlasting modifications in sexual health.

For males, this might imply persistent hypogonadism and infertility even after discontinuing steroid use.

For women, the deepening of the voice or clitoral enlargement may not reverse after stopping the steroids.

References:

PedsElite muscle gain

As Soon As the goal wholesome range is confirmed along with your medical specialist, a dosage plan will be organized.

Generally, men will start very low – under 100mg for a number of months, and then bloodwork is completed

to substantiate progress and whether or not the TRT dose should enhance.

If you’re trying to take such excessive doses of testosterone, you’ll

most likely be on the point where it’s going to make sense to stack other AAS to herald extra powerful anabolic effects.

It is probably the most frequent opposed occasion in older men receiving

testosterone substitute remedy (TRT) (40). This calculator helps visualise your entire Anabolic Steroids Cycle

by mapping peaks/amount of energetic steroid compounds (mg/day) inside your physique.

Helps to simply plot the active compounds/peaks on a

chart to better understand the influence of a steroid cycle.

Export/print your results in multiple formats similar to Image/PDF/CSV/XLS etc This calculator is

a heavily updated version of steroidcalc, which is not obtainable anymore over

the internet.

Follow-up data were obtainable for eight of the patients, of which one

progressed to end-stage renal illness within 1 month of biopsy.

The remaining seven sufferers either stabilized or showed a decrease

in serum creatinine levels and proteinuria after beginning medical therapy (in the form of ACE inhibitors,

ARBs, and/or renin inhibitors) and stopping AAS use. One of the

patients resumed AAS use and subsequently developed progressive renal insufficiency and an increase in proteinuria.

A trial in older hypogonadal men randomized to TRT with or

without the 5α-reductase inhibitor dutasteride famous no change in CEC (137).

CEC also remained unchanged in transgender males

(female to male) undergoing therapy with testosterone gel or injections (138).

In contrast, cross-sectional analysis demonstrated impaired CEC in AAS users in contrast with age-matched, strength-trained nonusers and sedentary controls

(139).

In my expertise, these cycles have their place, BUT you higher have an excellent purpose for desirous to go on this path as a result of it won’t be without

its downsides. Nonetheless, the method of esterification (attachment of

an ester) is perhaps the most critical think about a

steroid’s half-life. The bonded ester controls the speed at which the hormone is launched into your physique after injection. You’ll

discover testosterone steroids with completely different connected esters

– some have a short half-life, and others are very long or slow-acting.

Steroids have a robust anti-catabolic impact on muscular tissues (after all,

they are ANABOLIC steroids – the other of catabolic). Stress hormones like cortisol,

naturally rising throughout intense exercise, contribute to muscle breakdown and loss.

The most concerning attainable unwanted effects from Clomid are imaginative and prescient problems and potential long-term eyesight points that

are actually enough to boost the alarm. Clomid is taken into account very robust, whereas

Nolvadex is weaker, so some folks think about using both. However this does not take away the danger

of unwanted side effects; it’s more probably to enhance them.

In Distinction To HCG, a SERM will enhance your LH, which will permit you

to totally recover after a suppressive SARM cycle so you’ll have the

ability to maintain your features and never be weighed down with low testosterone

signs (which are debilitating for any male). If you do go forward with HCG, you’ll

use it alongside a SERM and never as a standalone drug.

Anavar can be utilized by some ladies, as it’s much less likely to

trigger virilization at low to reasonable dosages. We have found Olympus Males to be the most cost-effective supplier, with treatments ranging from $148 to

$200 per month. Anabolic steroids may increase the effect of anticoagulants,

such as warfarin. It is important to check the foundations with each particular regulatory group.

U.S. federal legislation restricts the use of these medicine by or on the lawful

written or oral order of a licensed veterinarian. Well, even should you do use HCG, you will find

yourself with suppressed LH, which is in a position to cause a testosterone drop.

A SERM can clean up this unfavorable effect of HCG while directly stimulating testosterone production.

According to a study from the Nationwide Institutes of Health,

incorrect dosing of anabolic steroids can lead to extreme well being risks, highlighting the

importance of correct measurements offered by the calculator.

These drugs may lower the injury that happens to muscular tissues during a

tough workout. Some folks additionally may like how their muscle tissue

look when they take these medication. Since large doses of AAS are administered during an AAS cycle, it is evident

that the event of gynecomastia during AAS use isn’t

the outcomes of an absolute or relative deficiency of

androgenic motion. Estradiol levels enhance dose-dependently with testosterone administration; however, the

rise is of proportionately lesser magnitude with rising doses, indicating saturation of aromatase exercise (23).

As such, it appears cheap to conclude that an absolute extra of estrogenic motion causes

the development of gynecomastia during AAS use, no matter its relative action compared with androgens.

Some AAS customers self-medicate with phosphodiesterase kind 5 (PDE5) inhibitors similar to sildenafil to counteract erectile dysfunction (65).

Some men (we may call them the lucky ones) are genetically programmed to

face up to the next DHT degree, while others are very sensitive to DHT, and only a small rise results in hair loss.

Even if you’re destined to experience some of these unwanted facet